If you have any questions, please feel free to contact us.| Email Us: info@dcheatpress.com

Views: 222 Author: Amanda Publish Time: 2026-01-10 Origin: Site

Content Menu

● Understanding Textile Fusing Machines

● Indonesia's Textile Machinery Landscape

● Local Textile Fusing Machine Manufacturers and Suppliers

● International Brands Serving Indonesian Apparel Factories

● COLORFUL as a Global Partner for Indonesian Buyers

● Choosing Textile Fusing Machine Manufacturers and Suppliers in Indonesia

● Typical Applications for Fusing Machines in Indonesia

● Technical Features to Look For in Fusing Equipment

● How COLORFUL-Style Equipment Fits Indonesian Needs

● Working With Different Types of Vendors

● Best Practices for Indonesian Buyers

● Future Trends in Fusing Technology for Indonesia

● FAQ

>> 1. What is the main function of a textile fusing machine?

>> 2. Why are Textile Fusing Machine Manufacturers and Suppliers important for Indonesian factories?

>> 3. What should Indonesian buyers check before choosing a supplier?

>> 4. How does equipment from companies like COLORFUL fit into the fusing process?

>> 5. What are common mistakes when importing fusing machines into Indonesia?

Indonesia is a strategic hub in Southeast Asia for Textile Fusing Machine Manufacturers and Suppliers, serving both domestic apparel brands and global export markets. The country's extensive garment clusters rely on advanced fusing, heat-press, and bonding technology to maintain consistent quality and high production efficiency.

Textile Fusing Machines bond interlining or other fusible components to fabrics through controlled heat, pressure, and time. This process creates stable shapes in garments, home textiles, and fashion accessories, helping products keep their form after repeated wear and washing.

In Indonesia's major production centers such as Bandung, Central Java, and Greater Jakarta, fusing machines are core equipment in shirt, suit, and uniform factories. They help manufacturers reduce defects, improve seam strength, and standardize quality across thousands of pieces per day.

Key roles of textile fusing machines in modern factories include:

- Enhancing collar, cuff, and waistband shape retention in shirts, uniforms, and fashion items

- Improving dimensional stability in structured garments like blazers, jackets, and trousers

- Reducing manual labor and human error compared with purely sewing-based reinforcement methods

Indonesia ranks among Asia's most dynamic textile and apparel producers, supported by spinners, weavers, knitters, dyers, printers, and garment exporters. To support this ecosystem, Textile Fusing Machine Manufacturers and Suppliers, both local and international, provide equipment for cutting, sewing, fusing, finishing, and printing.

Several characteristics define the Indonesian textile machinery landscape:

- Concentration of activity in West Java and Central Java, where many garment factories cluster around industrial zones

- Strong reliance on a mix of imported machinery and locally supported equipment for weaving, dyeing, finishing, and fusing

- Growing demand for automation, digital control, and energy-efficient machinery to keep up with global competition and sustainability requirements

For many producers, investing in reliable fusing machines is not a luxury but a necessity, as export buyers demand consistent performance and strict quality standards.

While Indonesia does not have as many specialized fusing-machine manufacturers as some larger machinery-exporting countries, it has a robust network of distributors and service providers. These businesses connect local factories with global Textile Fusing Machine Manufacturers and Suppliers and provide essential after-sales support.

Local and regional suppliers typically offer:

- Sales of continuous-belt fusing machines, flat-press fusing units, and multifunction heat presses

- Technical consultation to match machine specifications with fabric types, interlining choices, and production volumes

- Installation, operator training, preventive maintenance, and on-site repair services

For Indonesian garment producers, one of the biggest benefits of working with local Textile Fusing Machine Manufacturers and Suppliers or their agents is the ability to solve technical problems quickly. Shorter response times, local-language support, and familiarity with Indonesian working conditions make local partners especially valuable.

Beyond local distributors, many international brands serve Indonesian garment factories with advanced fusing, pressing, and bonding solutions. These global Textile Fusing Machine Manufacturers and Suppliers often sell through appointed agents or regional importers while maintaining technical standards used in Europe, East Asia, and North America.

International fusing and heat-press brands typically provide:

- Continuous-belt fusing machines designed for shirt factories, suit manufacturers, and large uniform producers

- Semi-automatic and fully automatic flat-press fusing machines suitable for smaller production runs or specialized operations

- Integrated systems combining fusing with other finishing processes such as pressing, steaming, or laminating

Because Indonesia exports to demanding global fashion markets, many factories prefer equipment from experienced Textile Fusing Machine Manufacturers and Suppliers known for:

- Stable temperature distribution across belts or platens

- Accurate pressure control to handle both delicate and heavy fabrics

- Long machine life, energy efficiency, and well-designed safety systems

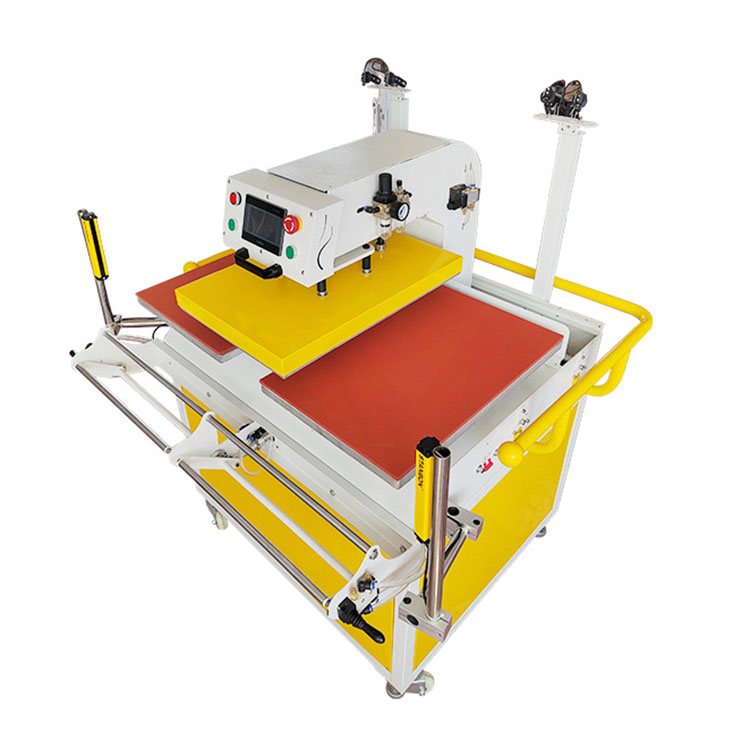

COLORFUL (dcsbheatpress.com) positions itself as a specialized manufacturer dedicated to research, development, production, sales, and service of high-quality heat transfer equipment, welding machines, and embossing machines. This expertise makes it a potential partner for Indonesian apparel producers searching for flexible solutions that complement traditional fusing lines.

By aligning with global textile and apparel demands, equipment from a company like COLORFUL can serve Indonesian buyers who need:

- Reliable heat transfer machines for garment decoration and branding

- Welding machines for technical textiles, bonded seams, and non-sewn constructions

- Embossing equipment that creates textured surfaces and value-added finishes

Although COLORFUL focuses on heat transfer and related technologies, its product direction fits naturally into the broader category of Textile Fusing Machine Manufacturers and Suppliers. Indonesian factories can integrate such machinery to combine fusing, decoration, and special effects in a single, efficient workflow.

Selecting the right Textile Fusing Machine Manufacturers and Suppliers is a strategic decision for any Indonesian garment producer. A wrong choice can result in inconsistent bonding, frequent breakdowns, and higher long-term costs, while a good choice can unlock productivity and consistent quality.

Key criteria when evaluating suppliers include:

- Temperature stability: Machines must maintain even heat across the working surface to avoid weak bonding or fabric damage.

- Pressure uniformity: Balanced pressure helps interlining adhere evenly and prevents bubbling or delamination.

- Capacity and throughput: Belt width, platen size, and production speed should match the factory's order volume and future growth plans.

- Material compatibility: The equipment should handle the full range of fabrics, interlinings, transfer films, and adhesives used in the factory.

- After-sales service: Availability of spare parts, technicians, and remote support is essential for continuous operation.

When dealing with Textile Fusing Machine Manufacturers and Suppliers from overseas, Indonesian buyers should also assess communication responsiveness, training resources, and documentation quality.

Indonesia's diverse textile sector creates a wide range of applications for fusing and heat bonding technology. Both large export-oriented factories and smaller local brands depend on fusing machines to deliver professional-quality products.

Common application scenarios include:

- Shirt and blouse production: Fusing collars, cuffs, fronts, and plackets for better stiffness and clean silhouettes.

- Formalwear and suiting: Fusing lapels, waistbands, front panels, and pocket areas to maintain shape and drape.

- Workwear and uniforms: Reinforcing stress points, logos, and badges while ensuring garments remain comfortable and durable.

- Sportswear and outerwear: Bonding laminates, reflective strips, tapes, and technical interlinings for performance and safety.

- Print-on-demand apparel: Using heat-press-style fusing equipment for vinyl, DTF, and sublimation transfers on small to medium runs.

In each of these use cases, Textile Fusing Machine Manufacturers and Suppliers that provide adjustable settings and robust construction help Indonesian factories respond to changing trends and increasingly short lead times.

Modern Textile Fusing Machine Manufacturers and Suppliers distinguish themselves through advanced technical features that simplify operation and improve consistency. Buyers should understand which features truly matter for their production environment.

Important technical aspects include:

- Digital control panels: These allow operators to set and monitor time, temperature, and pressure with a high degree of precision, store recipes for different materials, and reduce setup time between orders.

- Advanced heating technology: High-quality heating elements ensure faster warm-up, uniform heat distribution, and lower energy consumption over extended shifts.

- Automatic belt tracking and cleaning systems: These systems keep continuous belts aligned and clean, reducing fabric marks, contamination, and unplanned downtime.

- Safety and ergonomics: Features such as emergency stops, protective covers, and user-friendly controls support safer working conditions and less operator fatigue.

- Integration readiness: For larger factories, the ability to integrate fusing machines into line-control systems or data collection platforms can support Industry 4.0 initiatives.

Choosing Textile Fusing Machine Manufacturers and Suppliers that offer these features helps Indonesian businesses stay competitive and meet strict quality expectations from global buyers.

Manufacturers focused on heat transfer, welding, and embossing, such as COLORFUL, deliver equipment that complements classic fusing processes. For Indonesian factories, this combination is useful because it allows a single supplier group to support multiple stages of garment finishing.

Potential advantages of integrating such equipment include:

- Workflow consolidation: Fusing, transfer printing, and embossing can be arranged in logical sequences that reduce handling time and storage space.

- Design flexibility: Factories can add raised patterns, logos, and special textures while maintaining strong bonds and a professional appearance.

- Scalability: From small design studios to large production lines, the same family of machines can scale with the business, reducing the need to switch Textile Fusing Machine Manufacturers and Suppliers as order volumes grow.

This approach is especially powerful in Indonesia, where many producers serve both local fashion brands and international buyers with varying product requirements.

When sourcing fusing equipment, Indonesian buyers usually interact with one or more types of vendors within the broader group of Textile Fusing Machine Manufacturers and Suppliers. Understanding the typical roles of each vendor type can clarify purchasing strategies.

Common vendor categories include:

- Local machinery distributors: Provide sales, installation, training, and warranty service while representing global fusing and pressing brands.

- Regional heat-press and digital printing suppliers: Serve smaller apparel businesses and print shops with compact, versatile equipment that can handle both decoration and light fusing tasks.

- International fusing-machine brands: Offer high-end continuous-belt fusing systems and industrial presses designed for large-volume shirt, suit, and uniform production.

- Integrated equipment manufacturers: Supply heat transfer, welding, and embossing machinery, enabling customers to build multi-purpose finishing lines under one technology umbrella.

Combining these vendor types allows factories to balance cutting-edge technology with accessible local support, ensuring that Textile Fusing Machine Manufacturers and Suppliers are aligned with the company's long-term strategy.

To make the most of their investment, Indonesian businesses should follow structured best practices when dealing with Textile Fusing Machine Manufacturers and Suppliers, especially if they are importing equipment.

Recommended best practices include:

- Define production requirements clearly: Before requesting quotations, specify fabric types, interlining materials, daily capacity, and quality standards to avoid under- or over-specifying equipment.

- Request fabric tests and samples: Many suppliers can run sample fusing tests on customer fabrics and interlinings, providing reports or sample panels that show real results.

- Check references and case studies: Speaking with other users and reviewing success stories from similar factories can validate supplier claims.

- Evaluate total cost of ownership: Consider not only the purchase price but also energy consumption, maintenance demands, spare-part costs, and expected machine lifespan.

- Plan training and documentation: Ensure that operators and maintenance staff receive proper guidance, manuals, and troubleshooting resources in appropriate languages.

Following these steps helps Indonesian producers form long-term partnerships with Textile Fusing Machine Manufacturers and Suppliers and avoid costly mistakes.

As Indonesia moves further into higher-value manufacturing and branded fashion, fusing technology is also evolving. Textile Fusing Machine Manufacturers and Suppliers increasingly incorporate smart features, sustainability improvements, and design-friendly capabilities into their product lines.

Key trends shaping the future include:

- Greater automation: Automatic loading, unloading, and belt control systems that reduce manual labor and increase consistency.

- Data and connectivity: Machines capable of recording production parameters, error logs, and performance statistics for continuous improvement.

- Energy efficiency and eco-friendly design: Improved insulation, faster heating, and standby modes that reduce electricity usage and carbon footprint.

- Compatibility with technical and functional textiles: Fusing solutions adapted for laminates, membranes, and special-purpose fabrics used in sportswear and protective clothing.

By working closely with forward-looking Textile Fusing Machine Manufacturers and Suppliers, Indonesian producers can adopt these innovations gradually and maintain a strong competitive edge.

Indonesia has established itself as a major textile and garment production base, and this success depends in part on a strong ecosystem of Textile Fusing Machine Manufacturers and Suppliers. Local distributors, international brands, and integrated equipment makers together offer a wide range of fusing, heat transfer, welding, and embossing solutions for factories of all sizes. For Indonesian buyers, carefully selecting suppliers based on technical features, after-sales support, and long-term partnership potential is essential. When combined with clear production planning and good operator training, high-quality fusing technology enables consistent garment quality, higher productivity, and better positioning in demanding global markets.

The main function of a textile fusing machine is to bond fusible interlining or other materials to fabric using controlled heat, pressure, and time. This creates stable shapes and reinforces specific areas such as collars, cuffs, lapels, and waistbands so garments keep their structure during wear and washing.

Textile Fusing Machine Manufacturers and Suppliers provide the equipment and technical support that Indonesian factories need to meet strict quality and productivity targets. Without reliable machines and responsive service, producers can experience inconsistent bonding, higher defect rates, and costly downtime that reduce competitiveness in global markets.

Indonesian buyers should check temperature stability, pressure uniformity, machine capacity, and compatibility with their fabrics and interlinings. They should also confirm after-sales services such as spare-part availability, local technical support, training, and warranty conditions before committing to specific Textile Fusing Machine Manufacturers and Suppliers.

Equipment from companies like COLORFUL, which focus on heat transfer, welding, and embossing, complements traditional fusing machinery by adding decoration and special bonding capabilities. Factories can design integrated lines where fusing, transfer printing, and embossing follow one another, enabling flexible product designs and efficient workflows under a broader Textile Fusing Machine Manufacturers and Suppliers strategy.

Common mistakes include underestimating installation and training needs, ignoring local electrical and safety standards, and selecting equipment solely based on price. To avoid problems, buyers should work closely with experienced Textile Fusing Machine Manufacturers and Suppliers, plan for operator training, and ensure clear communication about specifications, logistics, and long-term service arrangements.

High-Tech Heat Pressing With Dual-Station Projection Alignment

Heat Transfer Paper Buyer's Guide 2026: Choose the Best Paper for Your Heat Press

Heat Transfer Paper Buyer's Guide 2026: How to Choose the Best Paper for Your Heat Press

Heat Press Maintenance Guide: Keep Your Machine In Top Shape

Heat Pressed Sublimation Patches: Complete Step-By-Step Guide For Hats, Jackets And More

The Ultimate Heat Press Buyer's Guide for Growing Apparel and Printing Businesses

Guide to Sublimation Blanks for High‑Quality Heat Press Projects

First Look at the New Sawgrass SG500 & SG1000 Sublimation Printers

Sublimation Printing in 2026: Complete Guide for Durable, Profitable Custom Products