If you have any questions, please feel free to contact us.| Email Us: info@dcheatpress.com

Views: 222 Author: Amanda Publish Time: 2025-12-27 Origin: Site

Content Menu

● Understanding What “Best” Really Means

● Comparing Popular Printing Technologies

● Why DTF Printing Leads in 2025

● Choosing the Right Heat Press

>> Heat Press Sizes Ideal for Small Businesses

● Step-by-Step: How to Choose the Best T-Shirt Printing Machine

● Real-World Scenarios for Small Businesses

>> Uniform and Promotional Supplier

● Optimizing Your Workflow for Better Efficiency

● Take Action: Build a Profitable T-Shirt Printing Business Today

● FAQs

>> 1. Is DTF better than DTG for small businesses?

>> 2. What is the minimum startup budget for T-shirt printing?

>> 3. Do I need an A3 heat press if I print small designs?

>> 4. Which machine works best for sports jerseys?

>> 5. How many shirts can an A3 DTF printer produce daily?

Starting or scaling a small T-shirt printing business in 2025 can be incredibly rewarding. However, the key to profitability lies in choosing the right equipment. The best T-shirt printing machine for small business owners should deliver consistent quality, flexibility across materials, and a good balance between cost and efficiency. This comprehensive guide explores key technologies, compares top options, and provides practical steps to help you select the ideal setup for your brand's growth.

The term “best” depends entirely on your specific business goals. The most expensive or advanced machine is not always the right choice. What matters most is your expected production volume, design complexity, available space, and budget.

- Fabric compatibility – cotton, polyester, blends, and dark vs light garments.

- Print quality and color accuracy for detailed or photo-real designs.

- Speed and daily output capacity for handling orders efficiently.

- Initial investment vs ongoing costs such as inks, films, or powder.

- Ease of use and maintenance, especially if you're a beginner.

In 2025, DTF (Direct-to-Film) and modern heat press systems have become the go-to solutions for small businesses due to their affordability, ease of scaling, and broad material compatibility.

Small T-shirt brands often choose between five leading technologies: DTF, sublimation, DTG, vinyl, and screen printing. Each has unique strengths and ideal use cases.

Technology | Best For | Key Benefits | Limitations |

DTF (Direct-to-Film) | Cotton, polyester, blends | Vivid colors, fine details, wide material range | Requires curing and powder application |

Sublimation | Polyester garments | Bright, durable prints | Works only on light polyester |

DTG (Direct-to-Garment) | Cotton shirts | Excellent detail, smooth gradients | Requires pretreatment and higher ink cost |

Vinyl Heat Transfer | Simple logos or text | Durable and easy to personalize | Labor-intensive for complex designs |

Screen Printing | Bulk uniform or promo orders | Low per-unit cost in volume | High setup cost and limited flexibility |

For small businesses, DTF offers the most versatility and return on investment, particularly for short-run or on-demand printing.

DTF technology provides a strong balance of quality, speed, and scalability. It is suitable for both startups and established custom apparel brands.

- Works seamlessly on cotton, polyester, and blends.

- Handles both light and dark garments with vibrant color accuracy.

- Low setup time and fast turnaround for small or custom orders.

- Minimal learning curve compared to DTG or screen printing.

- Large, repetitive bulk orders may still favor screen printing.

- All-polyester product lines might benefit from sublimation for long-term durability.

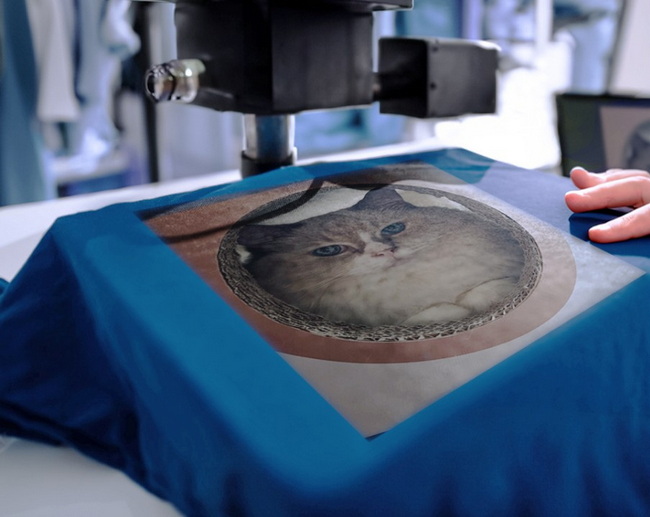

Even the best printing machine needs a reliable heat press to complete the transfer process. The heat press ensures durability, proper adhesion, and professional finish quality.

- A3 Heat Press (e.g., GS-804 model) – perfect for both A4 and A3 prints with quick setup and adjustable pressure.

- 16×20-inch Heat Press – a larger option for users managing higher daily volumes or bigger designs.

- Even temperature distribution across the platen.

- Adjustable pressure and precise digital controls.

- Safety features for continuous operation.

1. Determine your production goals. Estimate your expected order volume and product range.

2. Define your product focus. Cotton shirts, sports jerseys, tote bags, or mixed materials each have different ideal methods.

3. Set a realistic budget. Include equipment, consumables, software, and maintenance costs.

4. Evaluate space and power needs. Compact DTF and A3 heat presses fit into home studios easily.

5. Check for supplier support. Choose partners that offer after-sales service, spare parts, and detailed training.

- Volume: 50–300 shirts monthly.

- Setup: A4 or A3 DTF printer with matching heat press.

- Benefit: Great for testing new product ideas and custom drops.

- Volume: 300–1500 shirts monthly.

- Setup: A3 DTF printer with automatic powder shaker and 16×20-inch press.

- Benefit: High daily output with lower manual workload.

- Volume: Over 1000 shirts monthly.

- Setup: Screen printing for base designs, supported by DTF for small custom runs.

- Benefit: Keeps cost per shirt low on large orders while offering personalization flexibility.

Follow a consistent production process to maintain print quality:

1. Prepare artwork in high resolution and proper color mode.

2. Print on DTF film with correct resolution and ink density.

3. Apply hot-melt powder evenly and cure properly.

4. Press the film onto the garment at the recommended temperature and pressure.

5. Inspect output for color accuracy and adhesion strength before packaging.

Success in garment printing starts with selecting tools that grow with you. A high-quality DTF T-shirt printing machine paired with a reliable A3 heat press will help you deliver professional results fast, even from a small workspace.

If you want to upgrade your print quality, increase daily output, and expand your product range, invest in the right DTF setup today. Contact your trusted supplier to discuss customized packages that align perfectly with your printing goals. Take control of your creative business and make your next print your best one yet.

Yes. DTF printing usually offers more versatility because it works on cotton, polyester, and blends without needing pretreatment. It's cost-effective for both short batches and custom designs.

A basic A4 DTF setup with an entry-level heat press can often launch a small operation. Be sure to include inks, films, powder, and blanks in your total budget planning.

An A3 heat press provides more flexibility for larger prints and scales with your business growth. It's a worthwhile investment for long-term efficiency.

Sublimation and DTF printing are both excellent for sportswear. Sublimation excels on light polyester, while DTF can decorate darker or blended fabrics.

Depending on design complexity and speed settings, an A3 DTF printer can produce between 70 and 200 shirts daily when paired with an automated powder shaker.

Starting a Clothing Brand in 2026 with Just a Heat Press: Complete Guide for Serious Beginners

Heat Transfer Troubleshooting: Fix Common Heat Press Problems Like a Pro

How to Care for Clothes with Heat Transfers: Complete Washing, Drying, and Ironing Guide

Heat Press Maintenance Guide: How To Keep Your Machine Running Like New

Why 100% Polyester Shirts Are Your Best Choice for High‑Quality Sublimation Printing

Which Ink System Should I Choose for My New Sawgrass Printer?

What Is Siser EasyColor DTV? Complete 2026 Guide to Inkjet Direct-to-Vinyl Transfers